-595x335.jpg)

Product Introduction:

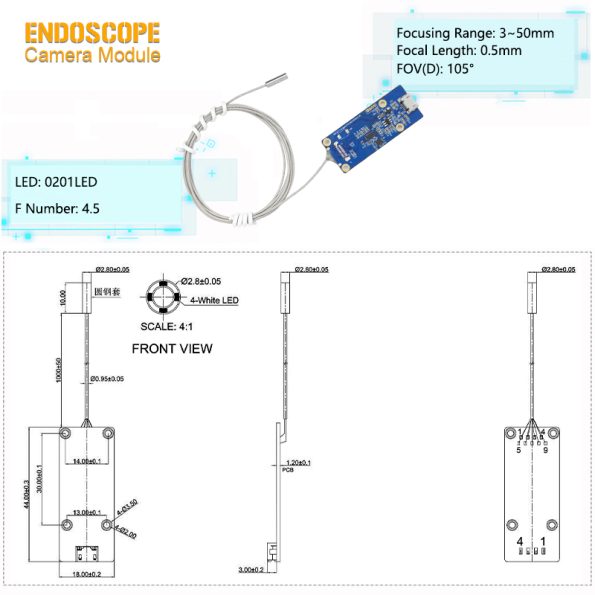

This is a new Separated Medical LED Endoscope Camera Module with Steel Shell, a core imaging component specially designed for high-precision observation scenarios in narrow spaces. It is equipped with a CMOS Color Image Sensor, featuring a 0.08MP Pixel specification, which can stably output QVGA Resolution images, ensuring the color reproduction and basic clarity of the observation images. The module has a diagonal viewing angle of 105° and a focal length of 0.5mm, supporting manual focusing operation, enabling clear focusing within a short distance range of 3mm to 50mm to meet observation needs at different distances. In terms of structural design, a Separated design scheme is adopted; the lens is connected to an independent DSP board through a precision wire bonding method, realizing the ultimate miniaturization of the module part. The DSP board is equipped with a Micro USB interface and supports USB 2.0 transmission speed, facilitating connection with external devices. The lens part adopts a 2.8mm diameter design and is equipped with an outer Steel Shell, balancing compact size and structural strength. At the same time, it integrates 4 0201-type LED fill lights to ensure uniform illumination in narrow and dark environments. The module is manufactured using the SMT (Surface Mount Technology) process and AA (Active Alignment) process that comply with EU RoHS certification, ensuring the stability and consistency of product quality.

Product Advantages & Features

- Miniaturization and High Integration: The Separated design combined with wire bonding connection minimizes the volume of the camera module body; the 2.8mm lens diameter and 0201-packaged LED fill lights allow it to easily enter most narrow spaces that traditional devices cannot reach, making it an ideal choice for integration into existing products.

- Wide-Angle Imaging Capability: The combination of a 105° wide viewing angle and a minimum focusing distance of 3~50mm enables capturing wide-range images at extremely close distances, which is very suitable for observing the internal structure of objects, inspecting gaps or components, and achieving no visual dead ends.

- Industrial-Grade Design and Stability: The lens Steel Shell provides good physical protection, while the SMT and AA processes adopted for the fill lights ensure accurate light source positioning and firm soldering. The overall structure is more durable, capable of resisting slight vibrations and impacts, and ensuring stability during long-term use.

- Versatility and Low Cost: The standard Micro USB interface and USB 2.0 protocol mean plug-and-play functionality, compatible with a wide range of hardware devices and operating systems. This greatly reduces development difficulty and integration costs, providing a cost-effective visual solution for various applications.

Product Application

- Minimally Invasive Medical Inspection: Suitable for dental root canal checks and otolaryngology nasal/ear cavity observations. The 2.8mm lens with Steel Shell safely enters narrow physiological cavities; 4 LED fill lights compensate for dark environments; manual focusing targets tiny lesions or foreign objects, aiding clear diagnosis.

- Industrial Precision Component Inspection: Used for automobile engine oil passage blockage checks and electronic component pin gap detection. The 105° wide angle reduces multi-angle operations; 3~50mm focusing switches between overall and local views; USB 2.0 enables real-time transmission; Separated design adapts to different industrial equipment.

- Consumer Electronics Maintenance: For mobile phone motherboard capacitor/resistor checks and laptop internal cable inspection. 0.5mm focal length + manual focusing clearly shows close-range electronic component appearance; 2.8mm lens penetrates narrow equipment areas; Micro USB connects to maintenance computers; Steel Shell resists slight collisions.

- Small Pipe & Appliance Internal Inspection: Fits water purifier filter pipe blockage checks and air conditioner capillary corrosion observation. 2.8mm lens easily enters small pipes; CMOS Color Sensor identifies pipe impurities and corrosion; fill lights ensure visibility of deep pipe images, helping locate faults quickly.

Brand Value Empowerment by SincereFirst

SincereFirst is guided by the brand philosophy of “Sincere Imaging, Precise Empowerment.” With over 30 years of deep expertise in optical and camera module development, every step—from refined production in Class 10/100 COB cleanrooms to quality validation through collaborations with Fortune Global 500 companies—is built on a commitment to reliability.

We not only develop high-performance, stable products through advanced processes but also translate technological excellence into tangible customer value through our 10-year warranty and one-stop customization services. Whether meeting the demand for precision in medical diagnostics, supporting efficiency in industrial inspection, or enabling detailed observation in scientific research, SincereFirst is dedicated to becoming your long-term partner in precision imaging.

If you are looking for a endoscope camera module solution that combines performance, quality, and comprehensive support, contact SincereFirst today—let’s explore new possibilities in precision imaging together.

.jpg)

-10-450x253.jpg)

-9-450x253.jpg)

-8-450x253.jpg)

-7-450x253.jpg)

-5-450x253.jpg)

-4-450x253.jpg)

-3-450x253.jpg)

-2-450x253.jpg)

-1-450x253.jpg)